METALLIC OPTICAL COATINGS

CILAS is an expert in the design and manufacturing of optical thin film coatings. By using dense technologies, CILAS optical components ensure the highest performances in the most severe environments.

CILAS product line includes dielectric coatings, protective coatings, black coatings and metallic coatings for large size optics up to 2m x 2m, all suited for defense, space, astronomy, scientific and industrial applications.

CILAS operates dense coating technologies including the largest optical coating platform in Europe using magnetron sputtering and is equipped with state-of-the–art metrology and qualification means in cleanroom environment.

An experienced team is at your service from design to industrial production through project management, according to ISO standards.

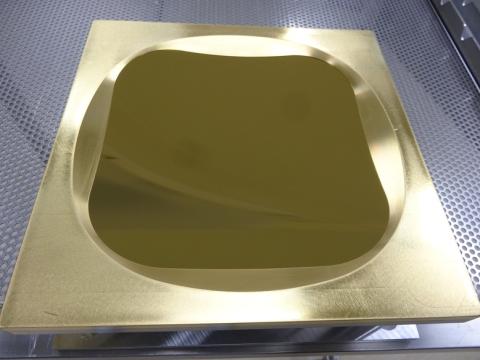

CILAS offers a large range of metallic coatings manufactured with magnetron sputtering process.

- Silver coatings, protected and enhanced, meet reflectivity needs in visible range up to 16µm, for industrial and space programs.

- Aluminum coatings, protected and enhanced, meet reflectivity needs in lower spectral ranges, for industrial, space and astronomy programs.

- Bare gold coatings are a solution for electrical conductivity purposes, as well as reflectivity needs in IR range for industrial and space programs.

All these coatings are suitable for glasses, Zerodur®, SiC, titanium, stainless steel and various aluminum types on components up to 2 meters by 2 meters, and benefit from space heritage.

Catalog coatings and specific designs available upon request.

Main references :

- Megajoule laser reflectors

- Proba-V and TROPOMI instruments

- Space telescope mirrors

- Euclid OGSE

- OAJ secondary mirror

- Solar simulators

| FEATURES OF METALLIC COATINGS | |

|---|---|

| SUBSTRATE MATERIALS | Silica, Zerodur®, Aluminum + NiP, Bare aluminum, Stainless steel, SiC, etc. |

| SUBSTRATES SHAPES AND DIMENSIONS |

Flat, concave and convex mirrors Up to diameter 2000 mm, 400 mm height and 1.5 tons |

| COATING TYPE | Protected and enhanced silver Protected and enhanced aluminum Unprotected gold |

| COATING PROCESS | Magnetron sputtering (dense coating) 900 m² of clean room ISO5 to ISO8 Grounding upon request |

| REFLECTIVITY | From 250 nm to 16 μm |

| COSMETICS | 5/C 1 x 0.16 per 100 mm pupil according ISO 10110-7 |

| ENVIRONMENTAL COMPATIBILITY | Suitable for severe environments (ATOX, radiations, vacuum, humidity…) Space heritage available upon request Cleanable |

| COATING AREAS | Full surface coating Coating free areas masked upon request |