BLACK COATINGS

CILAS is an expert in the design and manufacturing of optical thin film coatings. By using dense technologies, CILAS optical components ensure the highest performances in the most severe environments.

CILAS product line includes dielectric coatings, protective coatings, black coatings and metallic coatings for large size optics up to 2m x 2m, all suited for defense, space, astronomy, scientific and industrial applications.

CILAS operates dense coating technologies including the largest optical coating platform in Europe using magnetron sputtering and is equipped with state-of-the–art metrology and qualification means in cleanroom environment.

An experienced team is at your service from design to industrial production through project management, according to ISO standards.

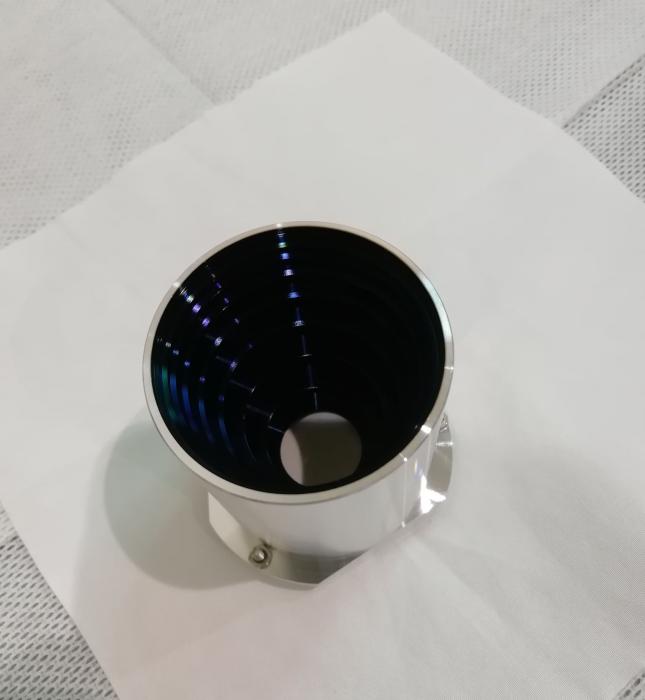

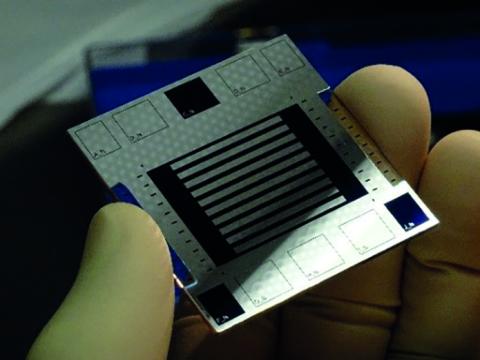

CILAS offers black coatings to mitigate straylight issues in optical systems for any spectral range between 380nm to 2.5µm, such as camera objectives, but also mechanical slits for optical diffraction purpose.

Thanks to the dense manufacturing technology, CILAS black coatings withstand severe environment conditions, for industry, scientific and space programs.

All these coatings are suitable for glasses, Zerodur®, SiC, titanium, stainless steel and various aluminum types on components up to 2 meters by 2 meters.

All these coatings can be applied on high quantities and large size components with typical dimensions up to 2 meters for anti-reflection coating, up to 400mm for dielectric mirror or dichroic, up to 200mm for polarizer or band pass filter.

Catalog coatings and specific designs available upon request.

Main references:

- TROPOMI

- Eyesat

- METimage

- Sentinel-5

| FEATURES OF BLACK COATINGS | |

|---|---|

| SUBSTRATE MATERIALS | Silica, Zerodur®, Titanium, Aluminum + NiP, Bare aluminum, Stainless steel, SiC, CFRP, etc. |

| SUBSTRATES SHAPES AND DIMENSIONS | Applicable to a wide range of components and shapes: slits, windows, prims, stripe filters, baffles, barrels, etc. Up to diameter 2000 mm, 20 mm height |

| COATING TYPE | Metal-dielectric multilayer coating |

| COATING PROCESS | Magnetron sputtering (dense coating) 900 m² of clean room ISO5 to ISO8 |

| COATING THICKNESS | < 1 μm |

| SPECULAR REFLECTIVITY | R < 1% over [400-900 nm] for AOI 0-30° Other spectral ranges upon request |

| HEMISPHERIC REFLECTIVITY | R < 1.6% |

| TRANSMITTANCE | T < 10-5 |

| THERMAL VACUUM | Qualified over [-165°C, 130°C] |

| COSMETICS | 5/C 1 x 0.16 per 100 mm pupil according to ISO 10110-7 |

| ENVIRONMENTAL COMPATIBILITY | Suitable for severe environments (ATOX, radiations, vacuum, humidity…) Space heritage available upon request Cleanable |

| CONTACT AREAS OR NON-USEFUL AREAS | Coating free areas masked mechanically or using photolithography techniques |